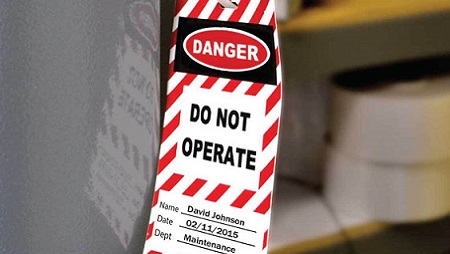

A pinch point is an area where one or moving objects come together with another object. All heavy equipment has pinch points. Examples include the articulation area of wheel loaders and dump trucks, pushing arms of dozers, and even somethings as simple as the cab door. You should always be aware of your surroundings when working on equipment, as the weight of the machines and force of the hydraulic pressure can make their pinch points extremely dangerous and even deadly. This safety video from Komatsu covers the basics of avoiding pinch points, such as pre-work inspections and Lock-out/Tag-out procedures.

Kirby-Smith believes in the “Culture of Zero” and having Safety First. Learn more about that here.